Versatile Applications and Key Benefits of Leafing Aluminium Paste

Release time:

2024-10-21

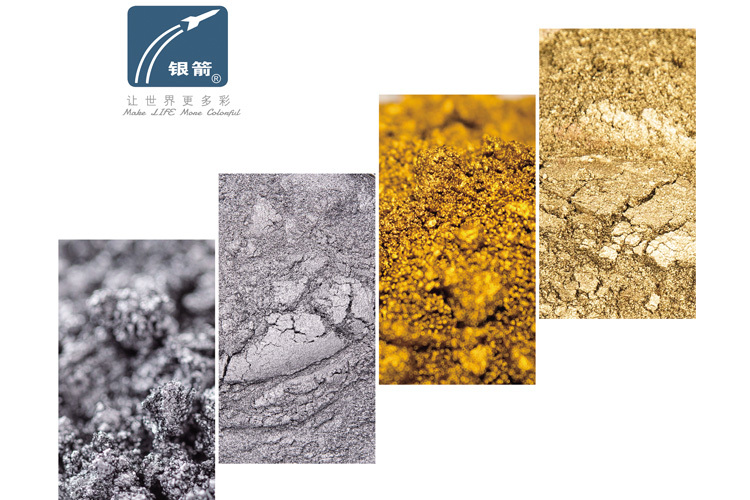

Leafing aluminium paste is a unique material, produced by grinding spherical aluminium powder into thin flakes. It floats easily on the surface of paint films and has excellent light reflection and heat insulation properties.

Leafing aluminium paste is a unique material, produced by grinding spherical aluminium powder into thin flakes. It floats easily on the surface of paint films and has excellent light reflection and heat insulation properties. Besides its strong hiding power and high whiteness, it also boasts impressive storage stability. When combined with low-acid resin systems, it creates a mirror-like finish. What’s even better? When mixed with silicon-based resins, the coating exhibits high heat resistance and stands strong against harsh weather conditions.

Top Applications of Leafing Aluminium Paste

1.Printing Inks: Superior Gloss Finish

Looking to add a metallic shine to your prints? Leafing aluminium paste is the go-to solution. It provides a high-gloss metallic effect, making printed materials more eye-catching and premium. This makes it perfect for high-end packaging and decorative printing.

2.Plastic Masterbatch: Enhance Surface Appearance

In the plastic industry, leafing aluminium paste offers superior coverage, evenly coating the surface of plastic materials with a smooth silver-white finish. This not only improves the quality of the plastic product but also makes it stand out in the market. It’s a win-win for both aesthetics and functionality.

3.Aerosol Paint: Stunning Metallic Finish

Leafing aluminium paste also shines in aerosol paints. Its excellent dispersibility ensures even distribution in the paint, resulting in a unique metallic sheen. Whether you’re doing DIY spray painting or automotive touch-ups, this paste helps achieve that perfect metallic look.

4.Anti-Corrosion Coatings: Durable and Protective

In anti-corrosion coatings, leafing aluminium paste offers exceptional resistance to corrosion. It forms a solid protective layer that shields the substrate from external elements. Plus, when combined with silicon-based resins, it adds heat resistance, making it ideal for high-temperature applications where durability matters most.

Key Benefits of Leafing Aluminium Paste

1.Weather Resistance

Leafing aluminium paste is highly durable, capable of withstanding adverse weather conditions. Whether it’s rain, wind, or sun, it ensures the coating maintains its high performance over time.

2.Strong Reflectivity and Heat Resistance

The high reflectivity of leafing aluminium paste helps reduce heat buildup on coated surfaces. When mixed with silicon-based resins, it also offers excellent heat resistance, making it ideal for coatings used in high-temperature environments.

3.Wide Range of Applications

From printing inks to plastic masterbatch, aerosol paints, and anti-corrosion coatings, leafing aluminium paste delivers reliable performance across various industries. It’s the perfect solution for adding metallic effects and protecting surfaces.

Contact US

With its outstanding reflectivity, weather resistance, and heat resistance when combined with silicon-based resins,Silver Rocket leafing aluminium paste has become an essential material across multiple industries. Whether you’re working with printing, plastics, spray paints, or protective coatings, this aluminium paste offers excellent performance and unique metallic finishes for your products.

Key words:

You can also learn more about the news