How to produce water-based aluminum silver paste? What are the advantages and disadvantages?

Release time:

2022-02-14

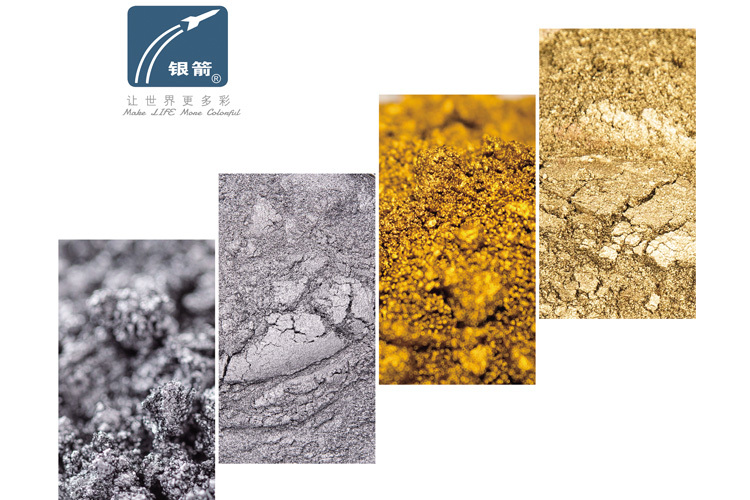

The series of water-based aluminum silver paste is divided into: young white water-based silver paste, fine flash water-based silver paste, medium flash water-based silver paste, super flash water-based silver paste, anti-electroplating water-based silver paste, ink special silver bar, etc. The water-based aluminum silver paste is divided into floating aluminum silver paste and non-floating aluminum silver paste, and it is further subdivided into water-based high floating silver, water-based floating silver, water-based suspended silver and water-based sinking silver, which will not be introduced here.

The series of water-based aluminum silver paste is divided into: young white water-based silver paste, fine flash water-based silver paste, medium flash water-based silver paste, super flash water-based silver paste, anti-electroplating water-based silver paste, ink special silver bar, etc. The water-based aluminum silver paste is divided into floating aluminum silver paste and non-floating aluminum silver paste, and it is further subdivided into water-based high floating silver, water-based floating silver, water-based suspended silver and water-based sinking silver, which will not be introduced here.

The production methods of water-based aluminum silver paste are as follows:

Direct grinding: add dispersant and antioxidant in the aluminum powder raw materials, and then use water-soluble solvent directly in the ball mill grinding.

② through the replacement of oily silver paste, also known as oil to water. With a high boiling point water-soluble solvent (such as: ethylene glycol butyl ether) by distillation method to replace the solvent oil, while adding some dispersant and antioxidant.

The first two are only through simple physical reactions, relying on some polymer materials to physically adsorb on the surface of silver paste to prevent the erosion of some water and impurities, which are primary products.

It is through the way of chemical reaction of nano silica particles deposited film adsorption on the surface of aluminum powder to prevent water, acid ions, alkaline ions, oxidants and other corrosion. Through the coating treatment of surface silica (also called nano-silica surface deposition coating), the surface of aluminum powder is coated with a dense protective film with a thickness of 50-100 nm.

These three production methods have their own advantages and disadvantages. The first direct grinding has advantages and low cost. Disadvantages: The production process is dangerous and the effect is general, such as: poor corrosion resistance, instability, etc.

The second kind is replaced by oily silver paste, and the advantage is that a better metal effect of aluminum silver paste appearance can be obtained. Disadvantages: poor corrosion resistance, instability, poor versatility.

The third nano-silica surface deposition coating, advantages: to obtain better results, higher acid and alkali resistance, stability. Disadvantages: high cost. Chemical reaction operations for degreasing, and silica deposition coating are performed. But also use the reaction kettle and other chemical equipment. The diameter of the nano-silica particles is about 10-30 nanometers, the better the reaction control, the finer and more uniform the nanoparticles, the denser the protective film, and the better the effect.

Key words:

You can also learn more about the news