Why is aluminum silver paste stored in the spring and summer rain season is particularly important

Release time:

2022-03-05

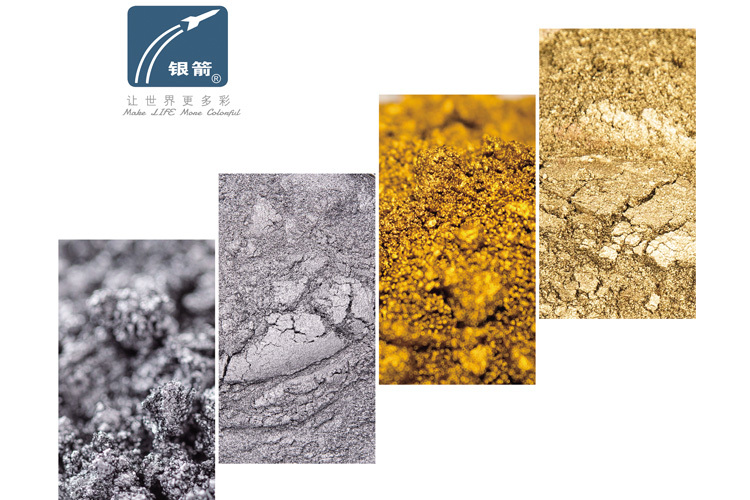

The main components of aluminum silver paste are aluminum flakes, solvents and additives. Although the surface of aluminum sheet will be coated with a layer of additives during the grinding process of aluminum silver paste, due to the high activity of aluminum itself, the increase of rain in spring and summer will have a significant impact on the storage performance, hue performance and safety of aluminum silver paste. Under normal circumstances, the aluminum sheet in aluminum silver paste maintains high activity and shows extremely high bright color after surface coating and polishing, which is also one of the reasons why aluminum silver paste is widely used.

The main components of aluminum silver paste are aluminum flakes, solvents and additives. Although the surface of aluminum sheet will be coated with a layer of additives during the grinding process of aluminum silver paste, due to the high activity of aluminum itself, the increase of rain in spring and summer will have a significant impact on the storage performance, hue performance and safety of aluminum silver paste. Under normal circumstances, the aluminum sheet in aluminum silver paste maintains high activity and shows extremely high bright color after surface coating and polishing, which is also one of the reasons why aluminum silver paste is widely used.

If the water content of aluminum silver paste exceeds its bearing range, the aluminum sheet will be oxidized and denatured quickly, resulting in a dark color. The storage of aluminum silver paste should also avoid contact with moisture. If the finished product of aluminum silver paste is exposed to excessive moisture, or moisture is directly infiltrated during transportation and storage, the aluminum silver paste will slowly react with water to affect its normal storage.

Aluminum is an active metal. The surface of aluminum powder used in our production is protected by a layer of alumina. During the production process, the alumina layer on the surface of the product will be ground off and then coated with additives. If the moisture content in the product is too high, aluminum powder will react with water to produce hydrogen and release heat. Hydrogen is flammable and explosive gas, which is easy to cause fire, explosions can also occur in confined situations. Therefore, from the perspective of safety, aluminum powder must be placed in a safe environment to avoid water.

The storage of aluminum silver paste is particularly important in the spring and summer rain season, especially in the southern region with strong rain and high temperature. Therefore, the waterproof work of aluminum silver paste finished products in storage and transportation should be strengthened.

Key words:

You can also learn more about the news