How to distinguish the quality of water-based aluminum silver paste? The finer the water-based aluminum silver paste, the stronger the hiding power?

Release time:

2022-01-07

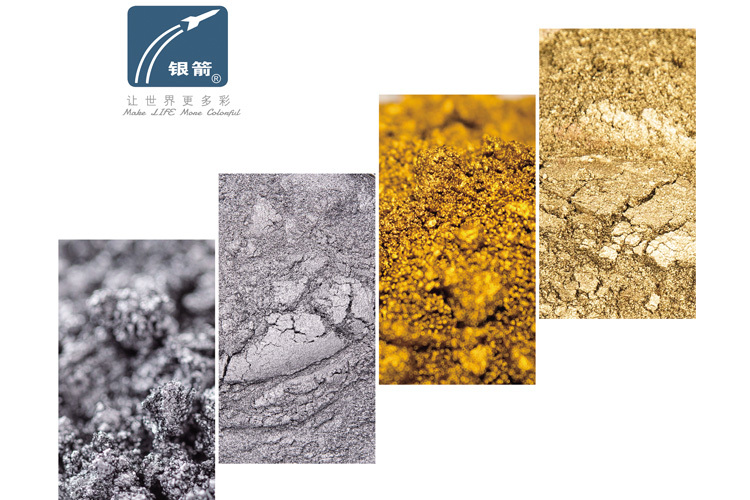

How to distinguish the quality of water-based aluminum silver paste? "The water-based aluminum silver paste with low solid content is definitely not good?" "The finer the water-based aluminum silver paste, the better the hiding power?" "The finer the water-based aluminum silver paste white brightness, the better?" problems such as these have been around us. Xiaobian knows that most manufacturers have just switched from oily system to aqueous system, or are still understanding aqueous system. The knowledge related to aqueous aluminum silver paste is not well understood, so the application selection is uncertain. Here, Xiaobian will briefly introduce some related contents of aqueous aluminum silver paste to you in several articles.

How to distinguish the quality of water-based aluminum silver paste? "The water-based aluminum silver paste with low solid content is definitely not good?" "The finer the water-based aluminum silver paste, the better the hiding power?" "The finer the water-based aluminum silver paste white brightness, the better?" problems such as these have been around us. Xiaobian knows that most manufacturers have just switched from oily system to aqueous system, or are still understanding aqueous system. The knowledge related to aqueous aluminum silver paste is not well understood, so the application selection is uncertain. Here, Xiaobian will briefly introduce some related contents of aqueous aluminum silver paste to you in several articles.

The solid content of water-based aluminum silver paste is high and low.

As the name implies, the water-based aluminum silver paste itself is composed of aluminum powder and solvent as the main components, and its aluminum powder content is also called solid content. By increasing the proportion of aluminum powder, the solid content of water-based aluminum silver paste can effectively improve the hiding power, thus reducing the addition amount.

At this time, someone will certainly ask again, is it definitely not good for water-based aluminum silver paste with low solid content?

As we all know, water-based aluminum silver paste is mainly coated in water, so it is not surprising that the finished product contains water. Many people think that the higher the solid content of the water-based aluminum silver paste, the better. In fact, otherwise, we should really focus on adding aluminum silver paste to the same system, the effect of the same amount of addition is different, rather than the surface of the solid content.

The finer the water-based aluminum silver paste, the stronger the hiding power?

The first thing to be sure is that the finer the water-based aluminum silver paste, the stronger the hiding power. However, this is not the fundamental way to solve the problem, because the real factor affecting the hiding power is the arrangement of the water-based silver paste. The arrangement of silver paste can determine the hiding power of water-based silver paste to a certain extent. The parallel arrangement of water-based silver paste paint film will have better hiding power and less addition ratio than the disorderly arrangement of silver paste paint film. So how to control the arrangement of silver paste is fundamental.

The finer the water-based aluminum silver paste white brightness, the better?

This problem is also related to the silver platoon. Because if the silver row is relatively flat, the naked eye will look more regular and white. On the contrary, if the silver rows are messy, there will be some dark and some bright. The overall effect is not good.

What is the difference in particle size of water-based aluminum silver paste?

The larger the particle size, the larger the gap between the silver powder, so it is necessary to add more proportion to achieve the purpose of covering. The small particle size of the water-based aluminum silver paste because the silver powder is arranged more closely, so the hiding power is relatively strong, but will lose part of the metal feeling as a price.

There are only a lot of water-based aluminum silver paste, which can not be understood unilaterally. It is correct to choose a suitable aluminum silver paste for your own products. Today, the editor will briefly introduce it to everyone.

Key words:

You can also learn more about the news