Special aluminum silver paste for aerosol paint has high efficiency and low cost to meet market demand

Release time:

2021-12-23

Galvanizing is a common anti-corrosion process in the surface treatment of steel structures, pipe fittings, angle frames and large fittings. The number of galvanized parts is huge every year. However, no matter in the electroplating construction process or in handling, many electroplating gaps will inevitably be formed, which is often fatal to the anti-corrosion of steel parts. Electrogalvanizing, also known as cold galvanizing in the industry, is the process of using electrolyte to form a uniform, dense and well-bonded metal or alloy deposition layer on the surface of the workpiece.

Galvanizing is a common anti-corrosion process in the surface treatment of steel structures, pipe fittings, angle frames and large fittings. The number of galvanized parts is huge every year. However, no matter in the electroplating construction process or in handling, many electroplating gaps will inevitably be formed, which is often fatal to the anti-corrosion of steel parts.

Electrogalvanizing, also known as cold galvanizing in the industry, is the process of using electrolyte to form a uniform, dense and well-bonded metal or alloy deposition layer on the surface of the workpiece.

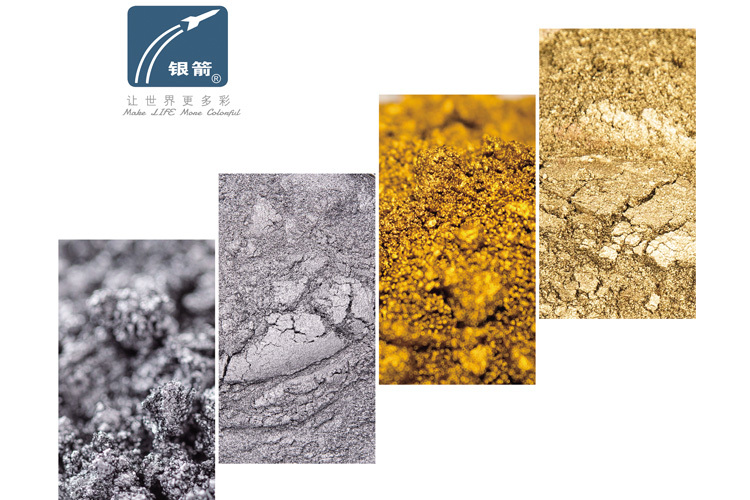

Silver powder aerosol paint is welcomed by the industry because of its fast and convenient use, high efficiency and low cost. The aluminum silver paste produced by Shandong Silver Arrow has carried out a large number of application tests according to the market demand. The special aluminum silver paste for aerosol paint introduced not only has a complete range of hue and can meet all the market needs, but also has been carefully developed and designed in performance according to the needs. It can reach minus 30 ℃ and minus 60 ℃ for three months without dimming. It is serving end users on five continents through aerosol paint manufacturers such as Pauli and Rainbow.

Key words:

You can also learn more about the news