Green Innovative Materials for Reshaping Aesthetics and Performance of Automotive Paint

Release time:

2024-08-26

With the rapid development of the automobile manufacturing industry and the increasing diversification of consumer demand, car paint is not only used as a protective layer of the body, but also a symbol of the appearance and quality of the vehicle. Among many automotive paint materials, aluminum silver paste has gradually become a bright star in the field of automotive paint with its unique metallic luster and excellent performance. This paper will discuss the application status, technical characteristics and future development trend of aluminum silver paste in automobile paint.

With the rapid development of the automobile manufacturing industry and the increasing diversification of consumer demand, car paint is not only used as a protective layer of the body, but also a symbol of the appearance and quality of the vehicle. Among many automotive paint materials, aluminum silver paste has gradually become a bright star in the field of automotive paint with its unique metallic luster and excellent performance. This paper will discuss the application status, technical characteristics and future development trend of aluminum silver paste in automobile paint.

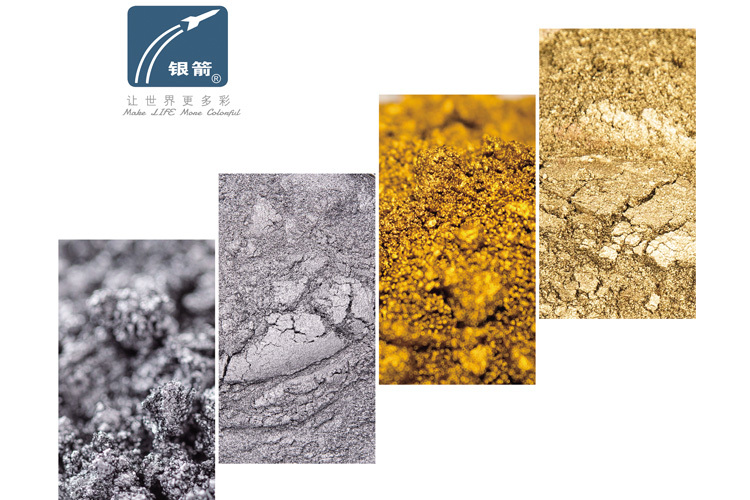

Basic characteristics of aluminum silver paste

Aluminum paste, as a widely used in automotive paint, motorcycle paint, bicycle paint and other fields of coating additives, with its unique physical and chemical properties to win the favor of the market. According to the type of solvent, aluminum silver paste can be divided into water-based aluminum silver paste and solvent-based aluminum silver paste. Solvent-based aluminum silver paste is well-known for its wide application in early automotive paint, but with the improvement of environmental awareness, water-based aluminum silver paste has gradually emerged because of its advantages of environmental protection and energy saving.

The main characteristics of aluminum silver paste include strong hiding power, high shininess, prominent metal texture, good smoothness and so on. These characteristics enable the aluminum silver paste to give the car paint a unique metallic luster and texture, so that the body presents a charming silver or flashing silver under the light, thereby enhancing the overall beauty and grade of the vehicle.

Application of Aluminum Silver Paste in Automobile Paint

Aesthetic effect

The application of aluminum silver paste in automobile paint is first reflected in its aesthetic effect. By adding aluminum silver paste, the car paint can show a charming metallic luster, make the body shine in the light, and enhance the visual impact of the vehicle. This metallic luster not only enhances the overall beauty of the vehicle, but also gives the vehicle a high-end and luxurious texture, which meets the personalized needs of consumers for the appearance of the car.

Anti-corrosion performance

In addition to the aesthetic effect, aluminum silver paste also has good anti-corrosion properties. As an important part of car paint, aluminum silver paste can effectively prevent the body from being corroded and prolong the service life of the car. Its excellent hiding power and floating make the coating more uniform and dense, effectively blocking the erosion of the external environment on the body. This is of great significance to improve the overall quality and reliability of the car.

Environmental protection and energy saving

With the continuous improvement of environmental awareness, water-based aluminum silver paste is more and more widely used in automobile paint. Compared with traditional solvent-based aluminum silver paste, water-based aluminum silver paste not only meets the requirements of environmental protection, but also reduces the heat consumption required for baking in the coating production process, and greatly reduces the energy consumption of production. This not only helps to reduce production costs, but also helps to promote the green development of the automotive paint industry.

future development trend

Promotion of environmental regulations

With the increasingly stringent environmental regulations, water-based aluminum paste will gradually become the mainstream products. In the future, the automotive paint industry will pay more attention to environmental protection and sustainable development, and promote the application of environmentally friendly materials such as water-based aluminum silver paste.

technological innovation

With the continuous progress and innovation of science and technology, the performance and quality of aluminum silver paste will be further improved. For example, the aluminum silver paste processed by a special process can make the body present an unpredictable light and shadow effect at a specific angle, and enhance the visual impact of the vehicle. In addition, key technologies such as particle size and dispersion of aluminum silver paste will also be continuously optimized and improved to meet the needs of the automotive paint industry for high-performance materials.

personalized needs

With the popularization of new energy vehicles and the development of intelligent network technology, the intelligent and personalized demand of automobile paint will continue to emerge. High-end coating materials such as aluminum silver paste will play an important role in this regard. By adjusting the ratio and process parameters of aluminum silver paste, car paint effects of different colors, gloss and texture can be achieved to meet the personalized needs of consumers for car appearance.

Conclusion

As an important part and innovative element in automobile paint, aluminum silver paste is leading the development trend of automobile paint industry with its unique charm and excellent performance. With the continuous advancement of technology and the continuous expansion of applications, we have reason to believe that aluminum silver paste will play a more important role in the future automotive paint field. At the same time, with the promotion of environmental protection regulations and the upgrading of consumer demand, the application of environmentally friendly materials such as water-based aluminum silver paste will become more and more extensive. In the future development, aluminum silver paste will continue to promote the green, intelligent and personalized development of the automotive paint industry.

Key words:

You can also learn more about the news