Application of Aluminum Silver Paste in Fluorocarbon Coatings

Release time:

2024-08-21

As a kind of high-performance coating, fluorocarbon coating has been widely used in many fields, such as architectural decoration, industrial anti-corrosion and so on. Its unique weather resistance, corrosion resistance, self-cleaning and excellent decorative effect make it a leader in the coating market. As one of the important raw materials of fluorocarbon coatings, aluminum silver paste adds unique luster and texture to it, making fluorocarbon coatings show more diversified characteristics in application.

As a kind of high-performance coating, fluorocarbon coating has been widely used in many fields, such as architectural decoration, industrial anti-corrosion and so on. Its unique weather resistance, corrosion resistance, self-cleaning and excellent decorative effect make it a leader in the coating market. As one of the important raw materials of fluorocarbon coatings, aluminum silver paste adds unique luster and texture to it, making fluorocarbon coatings show more diversified characteristics in application.

Basic characteristics of aluminum silver paste

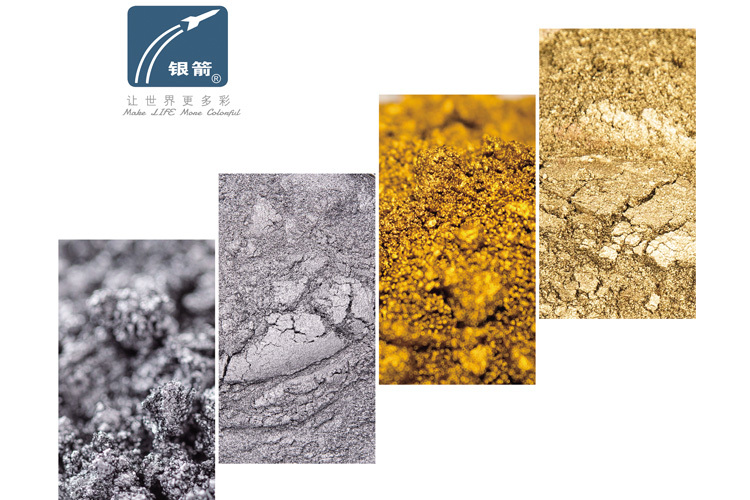

Aluminum paste is mainly composed of aluminum powder, solvent and additives, is a kind of pigment with silver luster. According to its behavior in coatings, aluminum silver paste can be divided into floating and non-floating two categories. Floating silver paste due to its low surface tension and floating on the surface of the coating, with high reflective and chrome plating effect, but the aluminum sheet is easy to fall off from the surface of the paint film, affecting the recoatability; non-floating silver paste can be completely wetted by the coating, evenly distributed in the entire paint film, forming a solid and stable coating film, suitable for recoating and overcoating light treatment.

Application of Al-Ag Paste in Fluorocarbon Coatings

The main raw materials of fluorocarbon coatings include fluorine resin and aluminum silver paste, which are processed through a series of complex processes and can form a strong and beautiful film on the surface of the object. The addition of aluminum paste not only improves the metallic luster and decorative effect of fluorocarbon coating, but also further enhances its weather resistance and corrosion resistance.

1. Improve the decorative effect

The combination of fluorocarbon coating and aluminum silver paste makes the coating surface show a dazzling silver luster, which enhances the overall appearance of the building. Whether it is exterior wall fluorocarbon coating or curtain wall aluminum veneer fluorocarbon coating, the addition of aluminum paste can make its appearance more eye-catching, improve the grade and quality of the building.

2. Enhanced weather resistance

The weather resistance of fluorocarbon coatings is already excellent, and the addition of aluminum silver paste is the icing on the cake. The aluminum powder in the aluminum silver paste has good oxidation resistance and corrosion resistance, and can effectively resist the erosion of harsh environments such as ultraviolet rays, acid and alkali, thereby prolonging the service life of the coating. In addition, the self-cleaning ability of the fluorocarbon coating also makes the coating surface not easy to stain and keep it clean for a long time.

3. Corrosion protection

In the application of fluorocarbon paint and fluorocarbon anticorrosive paint for steel structures, the anticorrosion effect of aluminum silver paste is particularly important. Fluorocarbon coating through multi-level coating, the use of each coating decoration, heat insulation, shielding, corrosion inhibition and cathodic protection, etc., to achieve long-term anti-corrosion protection of the substrate. The addition of aluminum paste not only enhances the anti-corrosion performance of the coating, but also improves the adhesion and mechanical strength of the coating, so that the coating can remain stable in harsh environments.

Selection and Application of Aluminum Silver Paste

In the production process of fluorocarbon coatings, the choice of aluminum silver paste is very important. On the one hand, it is necessary to choose coated water-based aluminum silver paste, which has good storage stability and weather resistance, relatively low price and high cost performance; on the other hand, the choice of particle size also needs to be comprehensively considered according to actual needs. Aluminum silver paste with large particle size is easy to construct and has good metal effect but poor hiding power. Aluminum silver paste with small particle size has good hiding power but is difficult to construct and has poor metal texture. Therefore, when selecting aluminum silver paste, it is necessary to determine the appropriate particle size range according to the specific application scenario and customer requirements.

In addition, in the use of aluminum silver paste also need to pay attention to its correct use. For example, an appropriate amount of organic solvent is added to the silver paste and stirred slowly to avoid damaging the surface coating of the silver paste. Fully soak, disperse and use as soon as possible to avoid volatilization of solvents and additives; Storage should be kept dry and avoid exposure to the sun and rain.

Conclusion

As one of the important raw materials of fluorocarbon coatings, aluminum silver paste plays an important role in improving the decorative effect of coatings, enhancing weather resistance and corrosion resistance. With the continuous progress of technology and the continuous expansion of the market, the application prospect of aluminum silver paste in fluorocarbon coatings will be broader. In the future, we will continue to explore and innovate the application technology of aluminum silver paste, and contribute more to the development of fluorocarbon coatings.

Key words:

You can also learn more about the news