Application and Advantage of Aluminum Silver Paste in Color Masterbatch

Release time:

2024-08-05

In the production process of plastic products, masterbatch plays a vital role. It can not only give the product rich and colorful colors, but also directly affect the appearance and performance of the product. In recent years, aluminum silver paste, as a unique metallic pigment, has been widely used in the manufacture of masterbatch because of its excellent luster and hiding power. This paper will discuss the application of aluminum silver paste in masterbatch and its many advantages.

In the production process of plastic products, masterbatch plays a vital role. It can not only give the product rich and colorful colors, but also directly affect the appearance and performance of the product. In recent years, aluminum silver paste, as a unique metallic pigment, has been widely used in the manufacture of masterbatch because of its excellent luster and hiding power. This paper will discuss the application of aluminum silver paste in masterbatch and its many advantages.

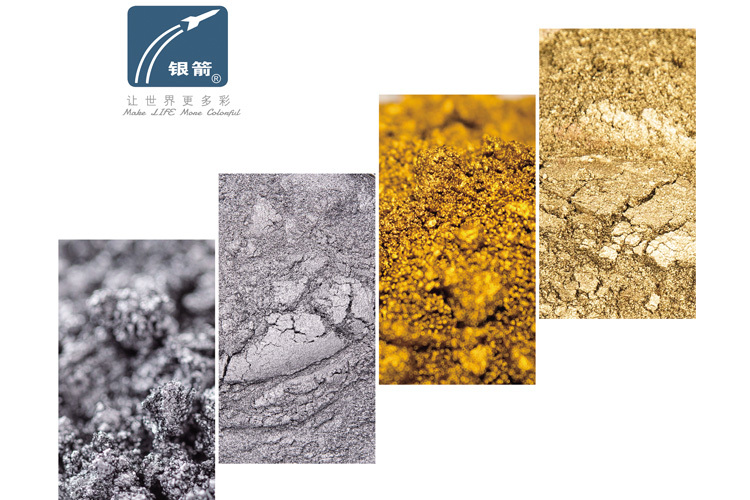

Basic characteristics of aluminum silver paste

Aluminum silver paste, the English name is Aluminiumpaste, also known as aluminum paste, flash paste or silver paste. Its main components are snow flake aluminum particles and petroleum solvent. After special processing technology and surface treatment, the surface of the aluminum sheet is smooth and smooth, the edge is neat, the shape is regular, and the particle size distribution is concentrated. This unique structure gives the aluminum silver paste excellent light reflection ability and metallic luster. Aluminum paste can be divided into floating and non-floating two categories, the former because of its low surface tension and floating on the surface of the coating, with a very high reflective and chrome plating effect; the latter can be completely wet coating, evenly distributed throughout the film, the film solid and stable.

Application of aluminum silver paste in masterbatch

Adding aluminum silver paste to the masterbatch can significantly improve the appearance of plastic products. The metallic luster of aluminum silver paste makes the surface of plastic products show a shiny effect similar to metal, which is visually attractive and can greatly enhance the grade and competitiveness of products. At the same time, aluminum silver paste also has good hiding power, can effectively hide the underlying color or defects, making the product appearance more perfect.

Advantages of aluminum silver paste in masterbatch

Enhance the visual effect: the introduction of aluminum silver paste enriches the color and effect range of masterbatch, making the appearance of plastic products more diversified and personalized. Its unique metallic luster can meet the market demand for high quality products.

Enhanced hiding power: The high hiding power of aluminum silver paste enables the masterbatch to better cover the background color or defects of the raw materials during mixing and processing, and improve the overall aesthetics of the product.

Improve weather resistance: high-quality aluminum silver paste, such as Shandong silver arrow aluminum silver paste, has good weather resistance, can resist the erosion of the external environment, and extend the service life of plastic products. This is especially important for products used outdoors.

Environmental protection trend: With the improvement of social environmental protection requirements, water-based aluminum silver paste has gradually become the trend of industry development. This product not only meets environmental protection standards, but also reduces environmental pollution while maintaining excellent performance.

Practical Application Case

In the market, many masterbatch manufacturers have begun to apply aluminum silver paste to their products. For example, the plastic fine white silver paste masterbatch produced by a manufacturer in Zhongshan City is widely praised for its high-quality aluminum silver paste. The product is not only bright color, high gloss, but also has good hiding power and weather resistance, is widely used in auto parts, electronic products shell and other fields.

Conclusion

In summary, the application of aluminum silver paste in masterbatch has brought significant improvement to the appearance and performance of plastic products. With the advancement of technology and the improvement of application skills, the application of aluminum silver paste in the masterbatch industry will be more extensive. In the future, with the increase of consumer demand for high-quality products and the improvement of environmental protection requirements, the demand for aluminum silver paste in the masterbatch market is expected to continue to grow. Manufacturers should seize this opportunity to continuously optimize product formulations and production processes to meet market demand and enhance product competitiveness

Key words:

You can also learn more about the news